Fabric Guide — How to choose

Based on our 10+ years of experience in crafting bike bags for all kinds of adventures, we’ve curated a selection of high-performance fabrics in a wide range of colors for you to choose from.

We’ve grouped our fabrics in four categories according to their weights. While our custom bags are available in any fabric we offer, we particularly recommend our midweight fabrics. They strike the best balance of performance, weight, look, and feel.

All of the fabrics we use are waterproof and plenty durable for on-road and off-road bike adventures. Learn more in the explainers below.

-

The durability of fabrics can be understood in terms of tensile strength and abrasion resistance. Unlike backpacks, bikepacking bags aren’t usually subjected to much tension. Abrasion occurs when there’s relative movement between the bag and bike frame. The modern technical fabrics we use are all very abrasion-resistant, heavier weights more so.

We maximize the longevity of our bags through thoughtful design that minimizes movement between the fabric and bike frame. Our well-fitting frame bags, rack-mounted rando bags, and Micro Panniers see little fabric wear in normal use. We reinforce high-wear areas with Hypalon.

This is to say, fabric durability shouldn’t be a major concern for most use cases. Unless you’re regularly subjecting your bags to extreme abuse or neglect, our premium midweight fabrics are plenty durable to last the lifetime of a bag. Ultralight fabrics benefit from care in use.

-

All the fabrics we use are waterproof. This is achieved with a waterproof multi-layer construction and durable water-repellent (DWR) treatment that causes water to bead on the surface.

C6 DWRs, which are based on long-chain PFCs, are harmful for humans and the environment and are being phased out. They are being replaced by SmartRepel Hydro coatings (ECOPAK™, RX30, RX36), sometimes called C0 DWR.

Since our bags are handsewn, not welded, they aren’t technically waterproof. In practice, they are highly water-resistant because we employ a variety of waterproofing techniques such as seam taping, floating liners, and smart seam placement. You might keep critical items in a light drybag and enjoy the unique design made possible by the sewn construction.

-

It’s good to be conscious of fabric weight, but fabric weight is a relatively small part of overall system weight. Consider that a complete bikepacking bag set made from ultralight fabric saves only couple hundred grams over a heavyweight fabric. The difference from the fabric isn’t significant compared to overall system weight of rider, bike, and gear, unless you’re counting grams. Our midweight fabrics strike a great balance and are perfectly suited for all bag models, especially frame bags.

The best all-around performers

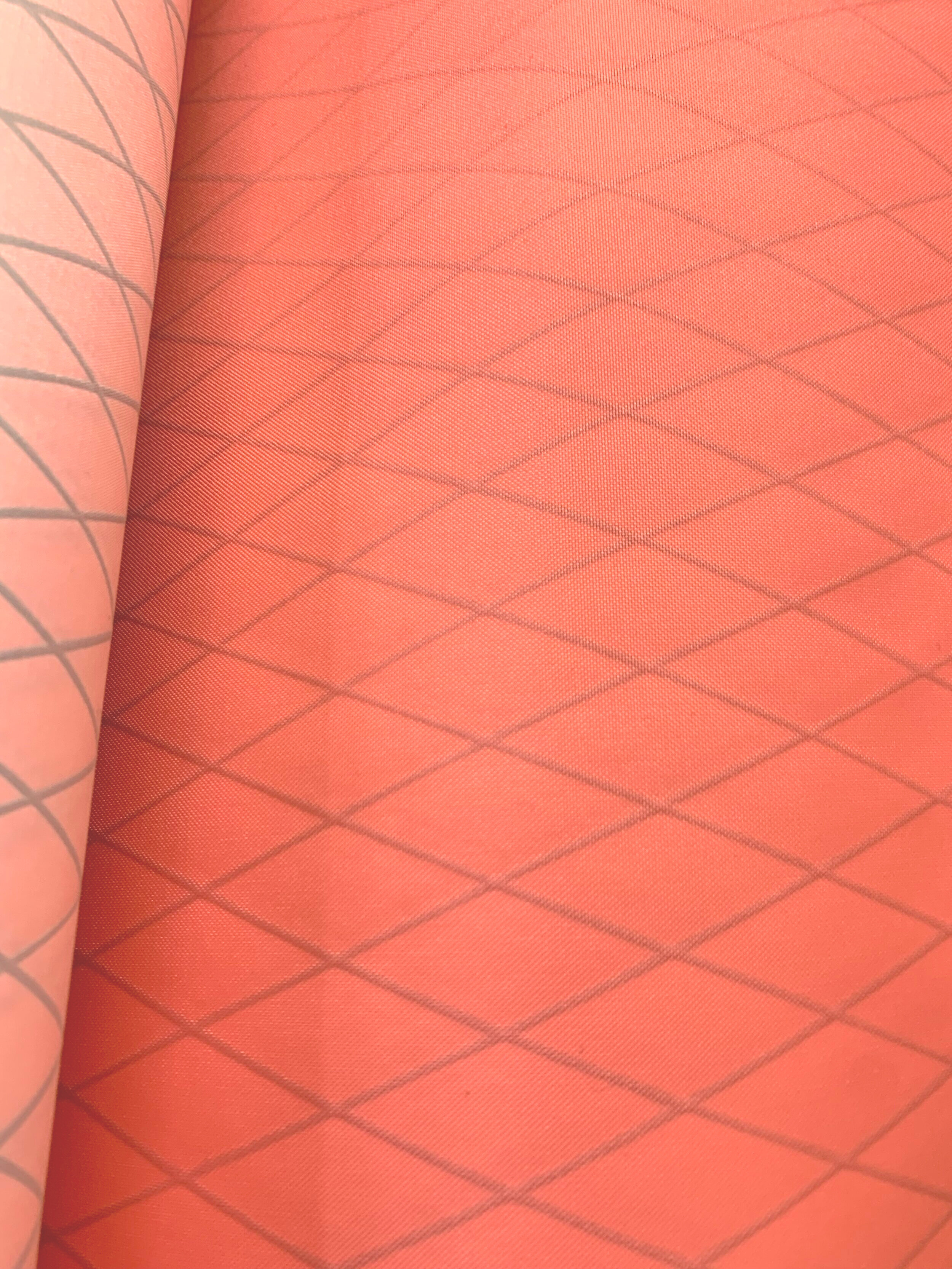

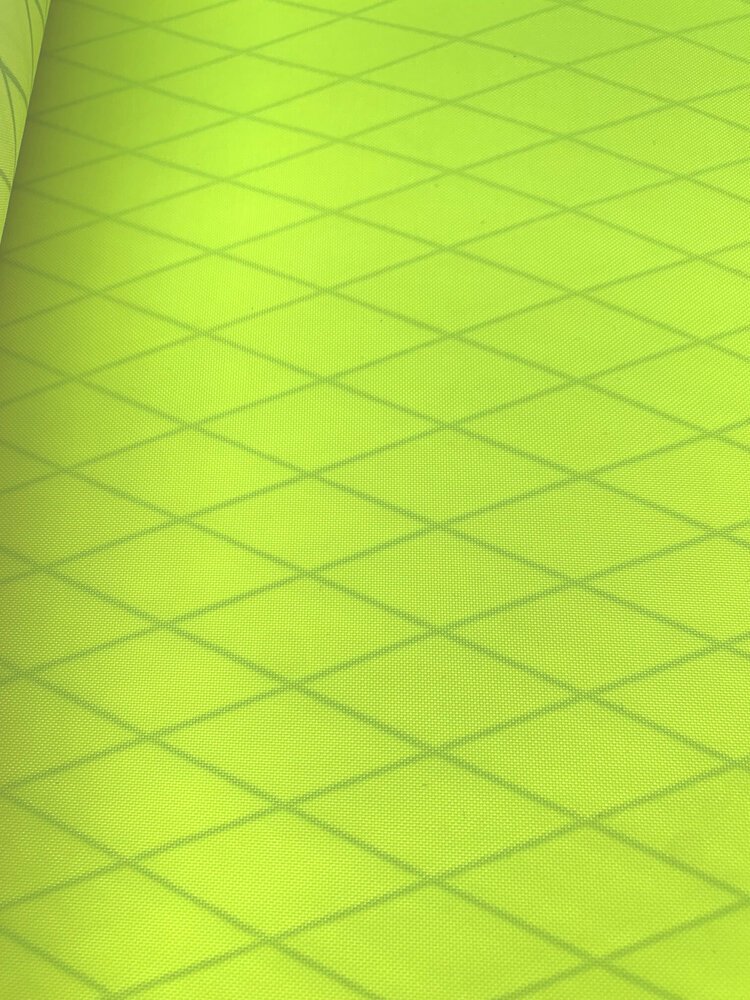

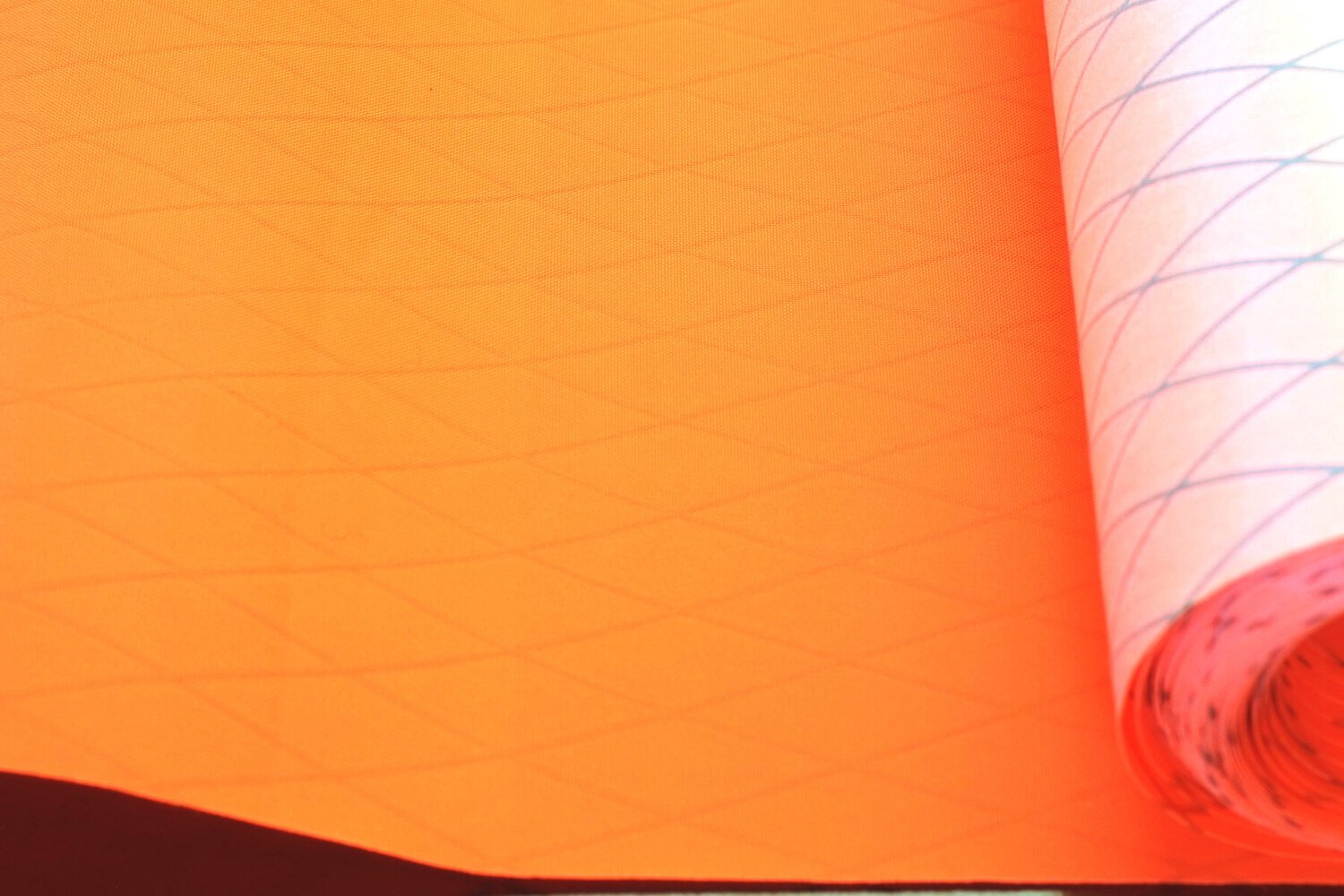

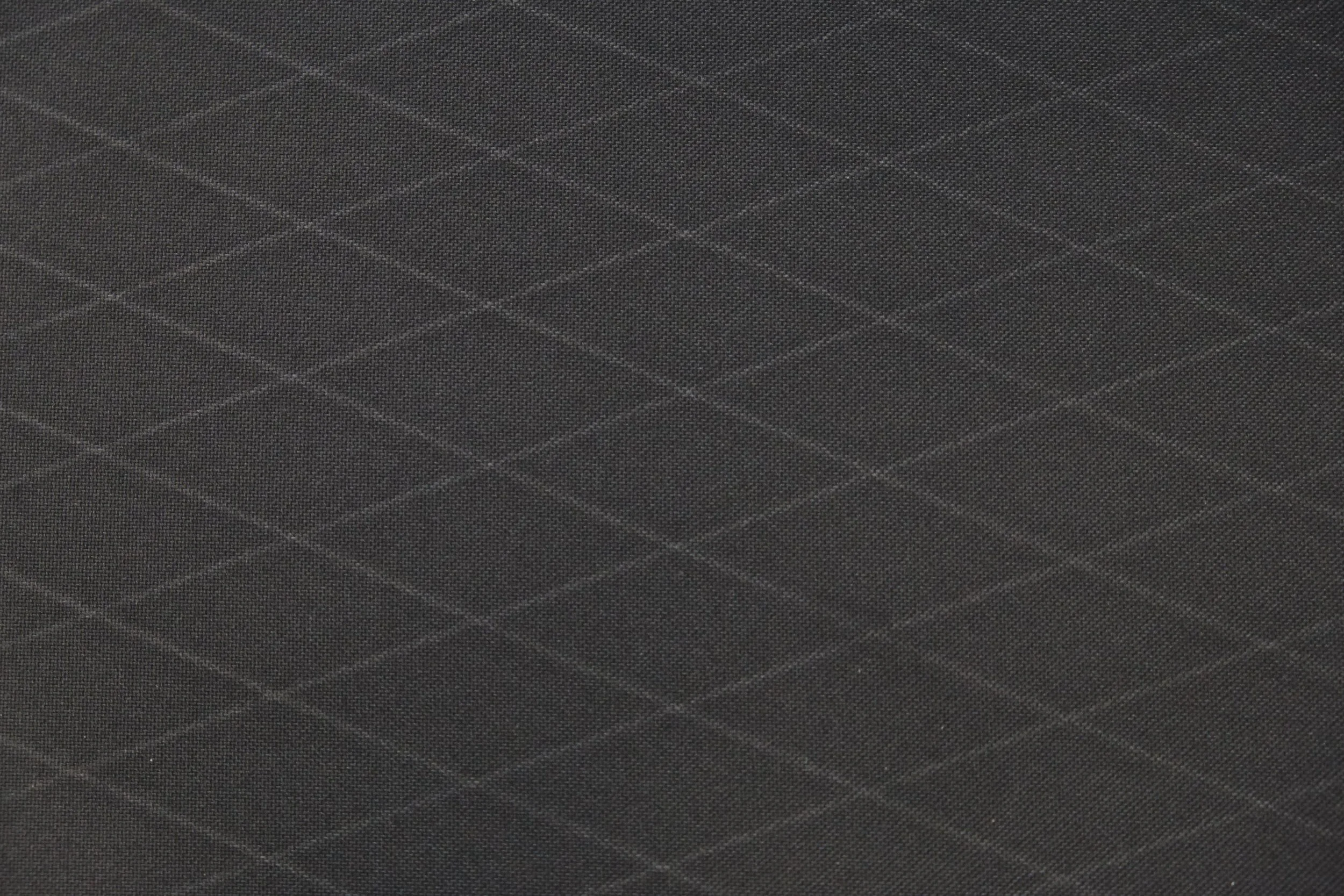

Offering a superb balance of performance to weight with a sleek finish, these midweight fabrics are our go-to. X-Pac® and ECOPAK™ are waterproof laminates with a distinctive cross-hatch ripstop layer, while CORDURA® is a time-tested single-ply fabric with a more classic uniform appearance.

-

Our most popular fabric, VX21 offers medium weight, high abrasion resistance, and an ideal stiffness for bikepacking bags. It’s a waterproof multi-layer laminate featuring a nylon face fabric, post-consumer recycled polyester ripstop ply, and a lightweight polyester backing, rounded out by a DWR finish. Made by Dimension Polyant in USA, China, and Germany, depending on the particular fabric.

-

A three-layer waterproof laminate that contains 100% post-consumer recycled polyester fabric made from reclaimed PET bottles. This grants it very high abrasion resistance for its medium weight. Made in the USA by Dimension Polyant with locally sourced raw materials.

-

This is a recycled and recyclable polyester-based alternative to the popular VX21. It offers the same great balance of weight and performance with 45° ripstop plies. Every meter of fabric contains around 20 reclaimed PET bottles. The C0 DWR is PFC-free. Made by Challenge Sailcloth in China.

-

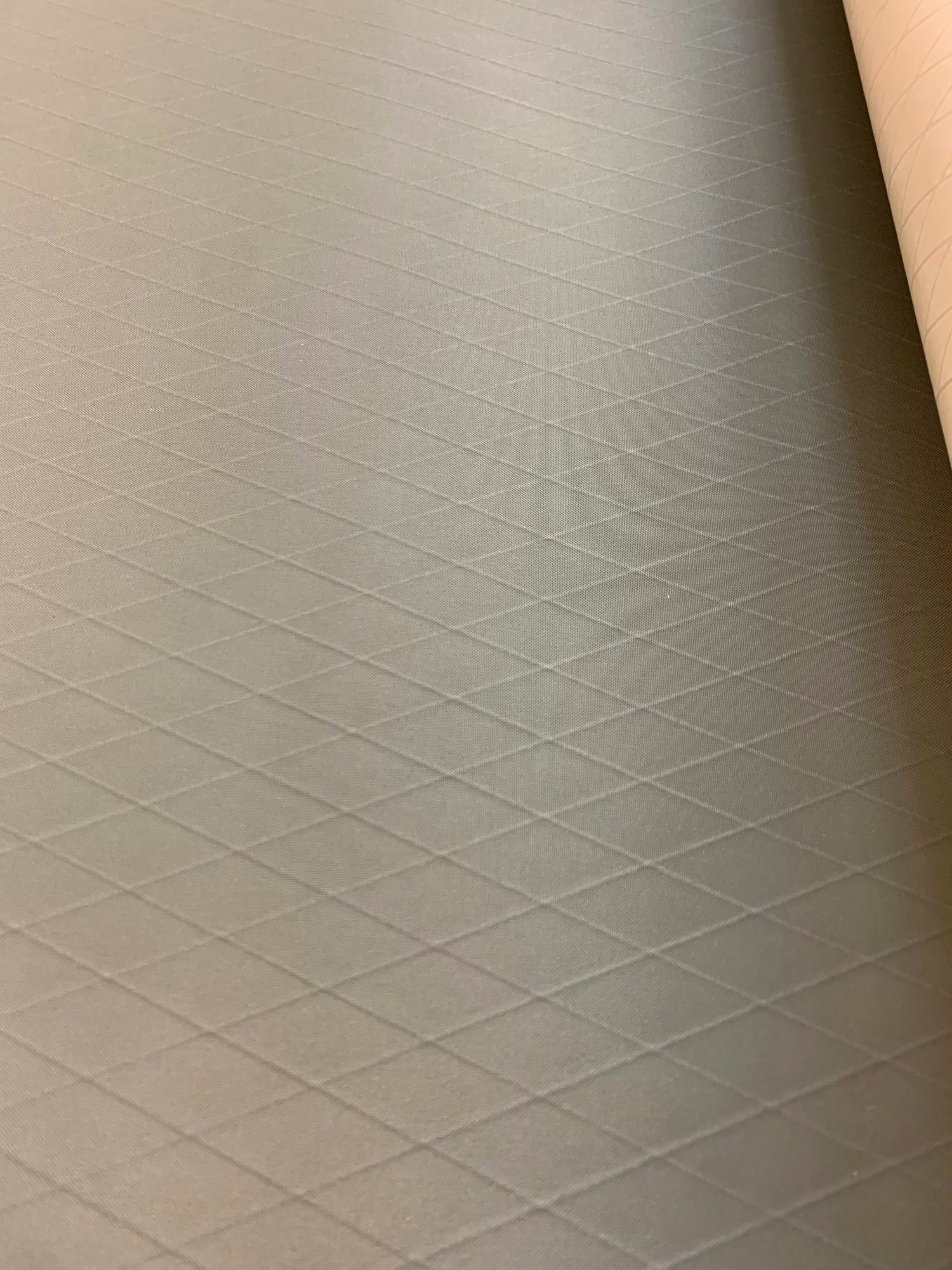

Tough and stiff, CORDURA® remains an ideal technical fabric that we love for its classic appearance. Our state-of-the-art CORDURA® is woven from nylon and backed by a durable PU film for waterproofness. It features a PFC-free DWR. Our CORDURA® is made in Germany.

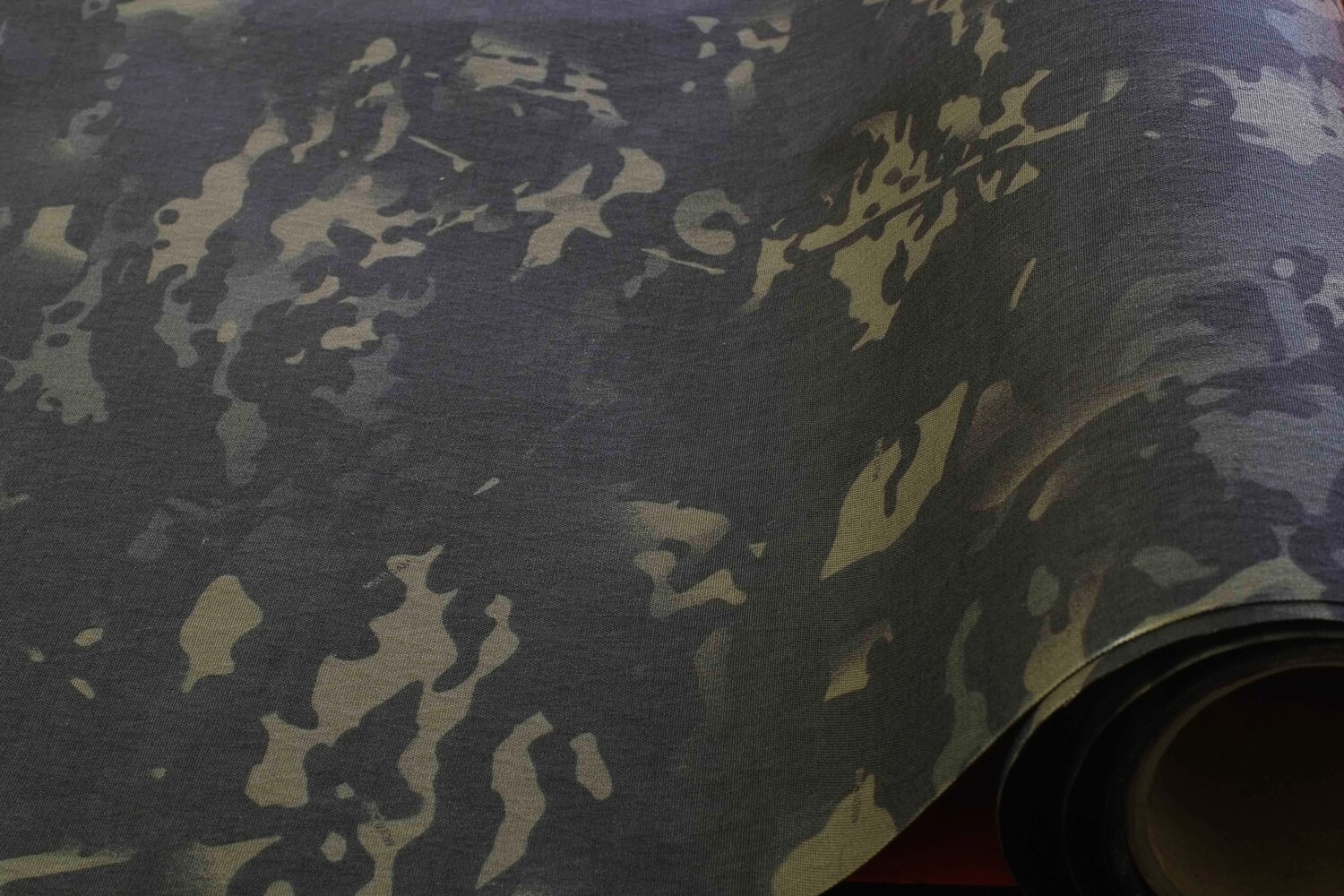

Heavy & Strong

With extreme durability exceeding the needs of nearly all bike applications, these heavyweight fabrics still have a firm place in our hearts. They have a coarse texture, stiff handfeel, and are available in unique colors.

-

These are rugged waterproof laminates with a burly 500d/1000d CORDURA® nylon face. Rated for military applications, X50 and X51 feature extremly high abrasion resistance, thickness, and weight. Made in USA by Dimension Polyant.

-

RX36 is a super durable polyester laminate made from post-consumer recycled PET bottles. It’s waterproof, stiff, heavy, and has a sheen that we love. We use it for our stock rando bags. The SmartRepel® Hydro DWR is PFC-free and biodegradabale. Made by Dimension Polyant in USA.

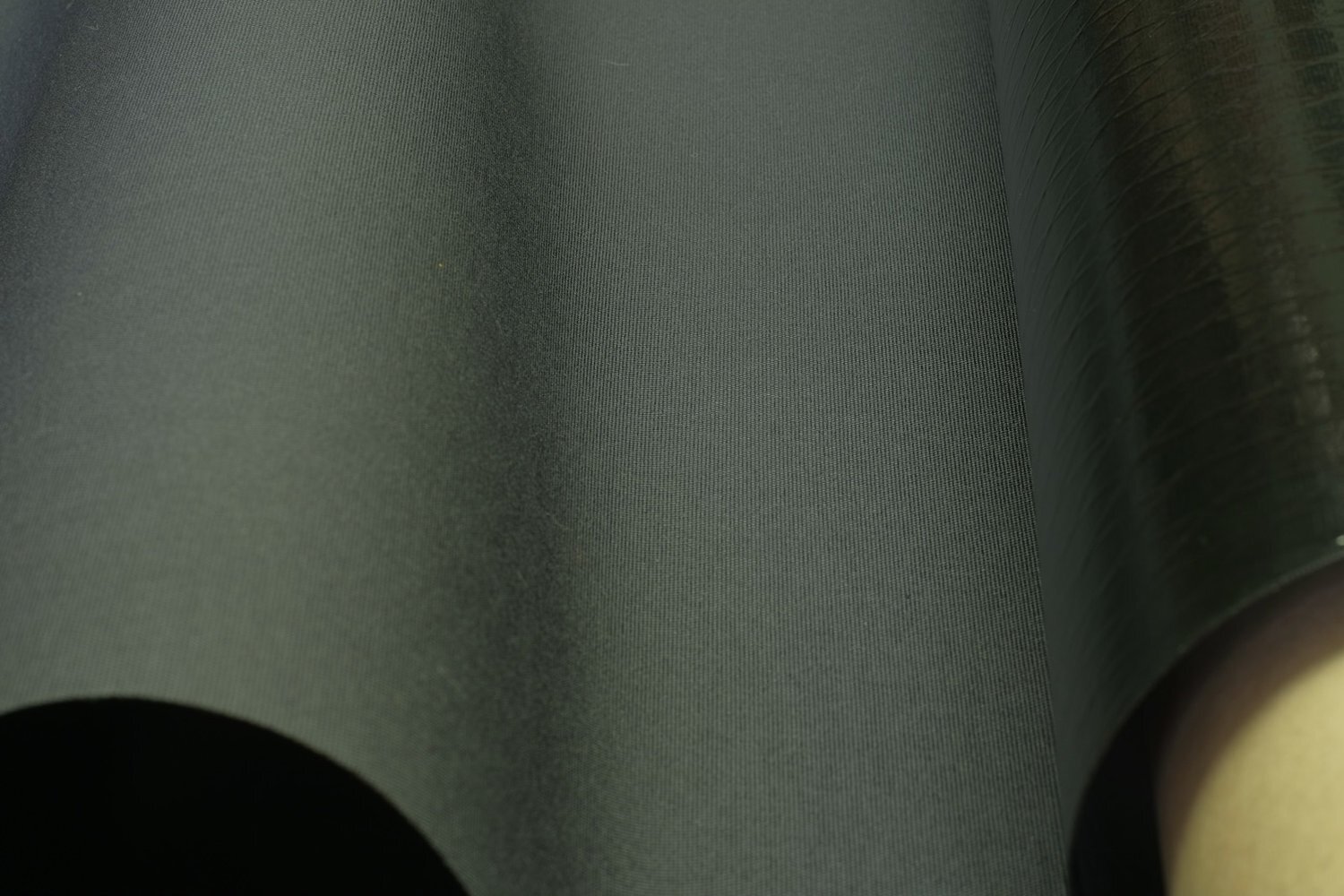

Ultralight

If you’re counting grams, lightweight fabrics save a little weight at the cost of durability. They are thin and soft, like tent fabric. A great choice for fast-and-light adventures that don’t get too rough.

-

Featuring the same multi-layer laminate construction and DWR as VX21, these are the lightest standard X-Pac® fabrics offered by Dimension Polyant. Made in Germany.

Ultralight (UHMWPE)

For the ultimate in ultralight strength, fabrics made with ultra-high-molecular-weight polyethylene (UHMWPE) fibers are unparalleled. These fibers are the lightest and strongest fibers commercially available, with a tensile strength much stronger than steel. When woven, their abrasion resistance is second to none.

Please note our made-to-order custom bags are not available in UHMWPE fabrics through our shop due to the very high cost of these materials. Get in touch via email if you’re still interested and prepared to pay a significant surcharge.

-

An ultralight fabric with exceptional tensile strength. DCF is made by sandwiching UHMWPE fibers between two sheets of polyester. The fibers give it a distinctive irregular pattern. It has a smooth feel.

-

Challenge Ultra™ fabrics weave UHMWPE fibers along with high-tenacity polyester for a more typical woven apperance. Ultra200x offers extreme strength and abrasion resistance at ultralight weights and very high cost. It’s backed up by an RUV film for waterproofing. Made by Challenge Sailcloth in China.

-

The lightest X-Pac laminate uses a 100% UHMWPE fiber weave for impressive strength and abrasion resistance. It features a Ciré finish. Made by Dimension Polyant.

-

Based on sailcloth technology, TX50 is an ultralight, ultra-thin 3-layer laminate with a 50d ripstop polyester face, Ultra™ cross ply, and PET backing. Made by Challenge Sailcloth in China.